History

In the beginning of the 70s, Hans Steffes, consulting engineer in the field of plastics engineering industry had the following vision:

From the blow-mould machine to the packaging

This vision became reality in 1973 and was constantly improved.

-

1973

Foundation of the first engineering company for plastics technology, project planning and the construction of various deflashing equipment, systems and leakage testing by means of additional controls and devices.

-

1975

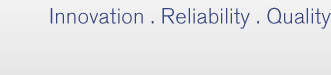

Construction of the first new type of leak testing equipment for bottles, jerry cans and drums.

- 1976

For all kinds of hollow containers made of plastic

- 1978

Production of container collecting stations and packaging aids - 1982

Development of leak testing equipment for sheet metal packaging - 1988

Construction of L-ring drum equipment with orientation and hole punching machine - 1992

Extension of the L-ring equipment by means of integrated weighing systems - 1994

Use of IBC leak testing equipment - 1996

Precise flow rate measuring devices for the automobile and pharmaceutical industry - 2001

Inline leak testing equipment for long stroke blow moulding machines - 2005

Chart display for the balancing technolog - 2010

complete factory automation - leak testers - 2011

introducing of the new developed high performance leak tester for grease cartridges - 2014

introducing of the new developed packing machine for bottles and jerry cans in trays - 2015

introducing of the new developed laser labeling system for aluminum containers in combination with a leak tester and a collecting station - 2016

introducing of the new developed capping machine for fully automatic feeding and placing of the dust cups on the article neck - 2018

introducing of the completely redesigned manual leak testing system for open top and bung holes barrels with the new Siemens TIA Portal control and rain hole drilling unit

- gathering stations with chutes and foil packers

- turning stations with packing patterns

- special conveying solutions

Today Steffes is one of the market leader with periphery solutions for QS-control in the blow moulding business and since 1976 delivered over 5.000 machines. Steffes exports to approx. 100 countries worldwide with an export rate of 70-80%.

Steffes as an exempt private company has been managed ever since with values such as customer satisfaction, product quality and product responsibility being of highest priority. Our customers estimate the high quality of the machines and also the competent and helpful customer service resulting from it.

News

07.05.2016

The automatic dust capping machine S-MA-WF-SO for canisters expands our product range.11.11.2015

The S-PACK-PAL-T-3000 is the further development of the S-PACK-PAL-T packing system03.08.2014

The name of our new development is S-PACK-PAL-T Deutsch

Deutsch Русский

Русский